E ka fella

-

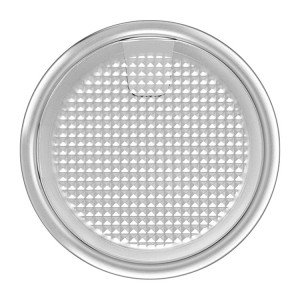

Tinplate FA Full Aperture Easy Open End 201

The tinplate aperture e feletseng e ka fela ha e na lintho tse kotsi bophelong ba batho, kahoo e na le thepa e se nang chefo 'me e sireletsehile haholo ha e sebelisoa ho paka lijo. Ka nako e ts'oanang, e boetse e na le matla a phahameng 'me e ke ke ea senya mohaho habonolo, kahoo e ka boloka sephutheloana se tsitsitseng se tiisitsoeng ka kopo. Ka hona, ha e bapisoa le mefuta e meng e tloaelehileng ea li-can, e khahla bareki haholoanyane.

bophara: 51.4mm/201#

Lintho tse bonahalang tsa Shell: Tinplate

Moralo: FA

Kopo: Lihlahisoa tsa lebese, Nut, Candy, Linoko, Litholoana, Meroho, Lijo tsa Leoatleng, Nama, Lijo tsa liphoofolo tse ruuoang lapeng, joalo-joalo.

Boikemisetso: Ho hatisa.

-

Tinplate FA Full Aperture Easy Open End 315

PACKFINE tinplate can lids le lihlahisoa tse tlase li nepahetse bakeng sa makotikoti a lijo. Ka ho roala ka mefuta e fapaneng ka hare, likoti tsa rona li ka sebelisoa bakeng sa litaba tse fapaneng, ho kenyeletsoa lekotikoti la nama, lekotikoti la tamati, lekotikoti la tlhapi, lekotikoti la litholoana le lijo tse omeletseng.

Khatiso e ka ntle ea lehlakore e entsoe ka mokhoa o ikhethileng, logo ea hau le lets'oao li ka bonts'oa ho eona.

Litlhaloso tsa rona tse felletseng li ka khotsofatsa tlhoko e ngata ea liphutheloana tsa tšepe, litekanyo tse ikhethileng le tsona lia fumaneha!

Lihlahisoa tsa rona li entsoe ka thepa ea boleng bo phahameng ka ho fetisisa le boqapi, ho netefatsa hore logo ea hau le lebitso la hau li tla bonts'oa ka khanya e ntle ka ho fetisisa.

Ikopanye le rona kajeno ho ithuta haholoanyane ka lihlahisoa tsa rona!

bophara: 95.5mm/315#

Lintho tse bonahalang tsa Shell: Tinplate

Moralo: FA

Kopo: Lihlahisoa tsa lebese, Nut, Candy, Linoko, Litholoana, Meroho, Lijo tsa Leoatleng, Nama, Lijo tsa liphoofolo tse ruuoang lapeng, joalo-joalo.

Boikemisetso: Ho hatisa.

-

Aluminium FA Full Aperture Easy Open End 401

Makotikoti a linotši a Packfine aluminium FA a buletsoeng ka botlalo a etselitsoe ho theha boiphihlelo bo monate ba tšebeliso.

Ka ho lumella bareki ho tlosa sekoahelo sohle, pheletso ea kotikoti ea seno e fetoloa kopi, ’me ba noang biri ba hoheloa ke ho etsisa ho tšeloa ha pompo haufi-ufi, ’me tatso eohle le monko o monate oa biri li otla likelello tsa ba noang. Moralo ona o boetse o etsa hore phepelo ea biri, biri ea maiketsetso, le lihlahisoa tse nang le khabone e tlase e be tse bonolo le tse sebetsang hantle.

Aluminium FA Full Aperture Easy Open End 401 e sebelisoa haholo bakeng sa linates, lipompong, phofo ea kofi, phofo ea lebese, joalo-joalo.

Bophara: 98.9mm/401#

Boitsebiso ba Shell: Aluminium

Moralo: FA

Kopo: Nut, Candy, Powder ea Kofi, Lebese la Lebese, Phepo e nepahetseng, Seasoning, joalo-joalo.

Boikemisetso: Ho hatisa.

-

Aluminium FA Full Aperture Easy Open End 603

Ho roala ka hare ho lesoba le felletseng ho ka fela ho fihlela litlhoko tsa bophelo bo botle le polokeho. Lihlahisoa tse pakiloeng ka eona li bonolo ho li jara le ho li sebelisa, li ka ikamahanya le maemo a leholimo a fapaneng, 'me li na le litšila tse ntle. Theko ea litšila e ka felisa lik'hemik'hale tse ka sebelisoang hape. Large bophara aperture e tletseng e ka qetella e loketse ho feta bakeng sa lijo, tse kang linate, lipompong, lebese phofo, joalo-joalo Bareki ka khetha bophara fapaneng ka qetella ho ea ka dikahare fapaneng.

bophara: 153mm/603#

Boitsebiso ba Shell: Aluminium

Moralo: FA

Kopo: Nut, Candy,Coffee Powder, Lebese la Lebese, Phepo, Seasoning, joalo-joalo.

Boikemisetso: Ho hatisa.

-

Tinplate FA Full Aperture Easy Open End 202

Packfine's Tinplate FA e koaletsoeng ka botlalo e ka fela e tiisitsoe ka botlalo, e tiile, 'me ha e chese mocheso. Sena se etsa hore li tšoanelehe haholo bakeng sa mefuta eohle ea lijo. Joalo ka ha u ne u lebelletse, liphetho tsohle tsa rona li fihlela litlhoko tse tiileng tsa EU le FDA. Lijo tsa makotikoting li bile teng lefatšeng ka lilemo tse fetang 200. Ha u nahana ka eona, hoa utloahala hobane e ka boloka lijo nako e telele ’me ea li sireletsa mongobong, likokoanyanang, libaktheria le likotsing tse ling.

Boima: 52.5mm/202 #

Lintho tse bonahalang tsa Shell: Tinplate

Moralo: FA

Kopo: Lihlahisoa tsa lebese, Nut, Candy, Linoko, Litholoana, Meroho, Lijo tsa Leoatleng, Nama, Lijo tsa liphoofolo tse ruuoang lapeng, joalo-joalo.

Boikemisetso: Ho hatisa.

-

Tinplate FA Full Aperture Easy Open End 401

Sesepa sa rona sa tinplate sa FA se ka fela se na le mekhoa e mengata. Li loketse lihlahisoa tsa seno hammoho le lijo. Lithako tsena tsa tinplate li loketse bakeng sa chisi ka brine haholo-holo.

Bakeng sa mefuta e fapaneng ea ts'ebeliso, Packfine e ka u khothaletsa mofuta o nepahetseng oa tinplate le lacquer e nepahetseng. Li-lacquers tsohle tseo re li sebelisang li amoheloa ke ba boholong ba amehang. Ho na le lera la ho tiisa ka hare, le ka ntlafatsang ho tiisoa ha makotikoti. Sekoahelo se nang le selikalikoe se hulang, se bulehang habonolo. Ho tšoaroa hantle holim'a metsi le likarolo tse boreleli ntle le ho senya matsoho.

Bophara: 98.9mm/401#

Lintho tse bonahalang tsa Shell: Tinplate

Moralo: FA

Kopo: Lihlahisoa tsa lebese, Nut, Candy, Linoko, Litholoana, Meroho, Lijo tsa Leoatleng, Nama, Lijo tsa liphoofolo tse ruuoang lapeng, joalo-joalo.

Boikemisetso: Ho hatisa.

-

Aluminiamo ea lijo le seno e felisa POE 603

Lijo le Beverage Aluminium Peel Off Ends li sirelelitsoe ka thata khahlanong le mongobo, UV le khase 'me li loketse lihlahisoa tse ngata tse kang phofo ea lebese, linoko, li-supplement, kofi kapa tee. Ka filimi e tlosoang ea aluminium, filimi e boreleli kapa e senyehileng. Peelable e ka qetella e siea moeli o lerootho kamora ho buloa, e leng se etsang hore e qetelle e bolokehile haholo kamora ho buloa mme e fana ka khanyetso e ntle ea sehlahisoa. Hona joale, peel off end e sebelisoa haholo ho pakang lijo.

-

Aluminiamo ea lijo le seno e felisa POE 209

Lijo tse omeletseng li hloka ho tšoaroa ka mokhoa o khethehileng pele li sebelisoa. Sephutheloana sa phofo ea lebese se ile sa qala ka mokhoa oa ho phunya. Lijo tse omeletseng li hloka ho koaloa ho boloka sehlahisoa se le secha ho fihlela se buloa le ho se sireletsa khanya le mongobo.

Ho fihlela lipheo tsena, peel of end package e nepahetse. E sireletsa lijo ho tloha linthong tsa tlhaho ha e ntse e boloka boleng ba eona ba phepo. Hape, ha e phuthetsoe, lekhapetla la lekhapetla le lumella sebaka pakeng tsa makotikoti ntle le ho a pshatla kapa ho a senya.

-

Aluminiamo ea lijo le seno e felisa POE 211

Lino tse phuthetsoeng ka makotikoti a peel off li bonolo ho li sebelisa le ho li boloka li hloekile. Ka mofuta ona oa ho koala, o ka etsa bonnete ba hore sehlahisoa se bolokehile ebile se sireletsehile nakong ea polokelo le lipalangoang ntle le ho lutla kapa ho senyeha. Tlosa ts'ireletso ea ts'ireletso ho netefatsa hore basebelisi ba khona ho fihlella habonolo feela ntle le ho tšoenyeha ka polokeho. Mofuta ona oa ho qetela o tšoarella haholo. Eseng seo feela, empa e boetse e sebetsa hantle ho boloka litaba. Hape, e lumella lijo ho bolokoa nako e telele.

-

Aluminium ea lijo le seno e felisa POE 300

Ha batho ba sebelisa mekhoa e tloaelehileng e bulehileng habonolo, ha ho pelaelo hore ba kotsing ea ho lematsoa ke mathōko a hlabang.ka khonaQETA. Leha ho le joalo, theebolae qetella ho feta ho tlatsa bofokoli bona. Ka lebaka la sebopeho sa tsona se bonolo, makotikoti a peel off a bonolo ho arola ha a ntse a netefatsa polokeho ea mosebelisi. Hape, kaha lisebelisoa tsa bona li bolokehile, ha ho hlokahale hore batho ba tšoenyehe ka hore na ba tla ama lijo tsa makotikoting.

-

Aluminiamo ea lijo le seno e felisa POE 305

Bahlahisi ba lijo ba ka sebelisa Peel Off End ho ntlafatsa boiketlo, ho sireletsa bocha ba sehlahisoa le ho theha phapang ea mofuta. Peel Off End e fana ka ho tlosoa kapele le ha bonolo 'me e na le liphanele tse tšesaane, tse tenyetsehang tse tiisitsoeng mocheso ho tšepe e thata kapa selikalikoe sa aluminium. Bareki ba hloka feela ho tšoara tabo e nyane holim'a sekwahelo le ho bula sephutheloana ka boitšisinyo bo bonolo le bo boreleli, lipheletsong tsena li etsa hore ho be bonolo le ho potlaka hore bareki ba bule makotikoti a lijo.

-

Aluminiamo ea lijo le seno e felisa POE 307

Lilemong tsa morao tjena, Peel off end e fetohile sehlahisoa sa sejoale-joale ebile se sebelisoa hangata, haholo bakeng sa lihlahisoa tse omeletseng. The can end e na le tinplate kapa sekoaelo sa aluminium mocheso se tiisitsoeng ka foil ea aluminium. E thusa ho theha tsela e bonolo ea hore moreki a bule kapa a epolle ntle le ho sebetsana le mochini o bulang lekoti le ntle le mathata a mangata. Ka lebaka leo, liphutheloana tse ngata li fetola likoahelo tsa tsona tse ka holimo hore e be likheo tse khaotsoeng hobane ts'ebetso ea canna e lula e tsitsitse, e bolokehile ebile e loketse bareki.